INDUSTRIAL

(WASTE) WATER USE.

Industries can use any water source depending on the abundancy and the cost of water treatment. Well water, surface water and tap water are often used as process water after a standard treatment of make-up water: filtration, softening, ultrafiltration, demineralisation, RO. Wastewater treatment can be done biologically or through physico-chemical treatment: IEX, RO, demineralisation. The concept of the future is zero liquid discharge, or medium liquid discharge, through evaporation where the wastewater flows are minimized and high amounts of useful clean water are reclaimed. Water scarcity forces the industries to rethink their water use and start reusing water. Wastewater effluent is often treated by UF-RO and reused in the process. Rainwater captured from roofs and parking lots is also a valuable water source for industries.

Agriculture mainly uses well water and tap water for hygienic use and drinking water for animals. Filtration, softening and disinfection of the water are standard treatment practices. Surface water is mostly used as irrigation water very often without any treatment. Irrigation demands high volumes of water and in many cases reclaimed water can perfectly be used for irrigation (depending on the crop type). Wastewater treatment and effluent reuse for irrigation is a future circular model for agricultural water use.

We are visionaries in industrial water treatment.

CHANGE STARTS WITH A VISION.

TOWARDS

CLOSING THE LOOP.

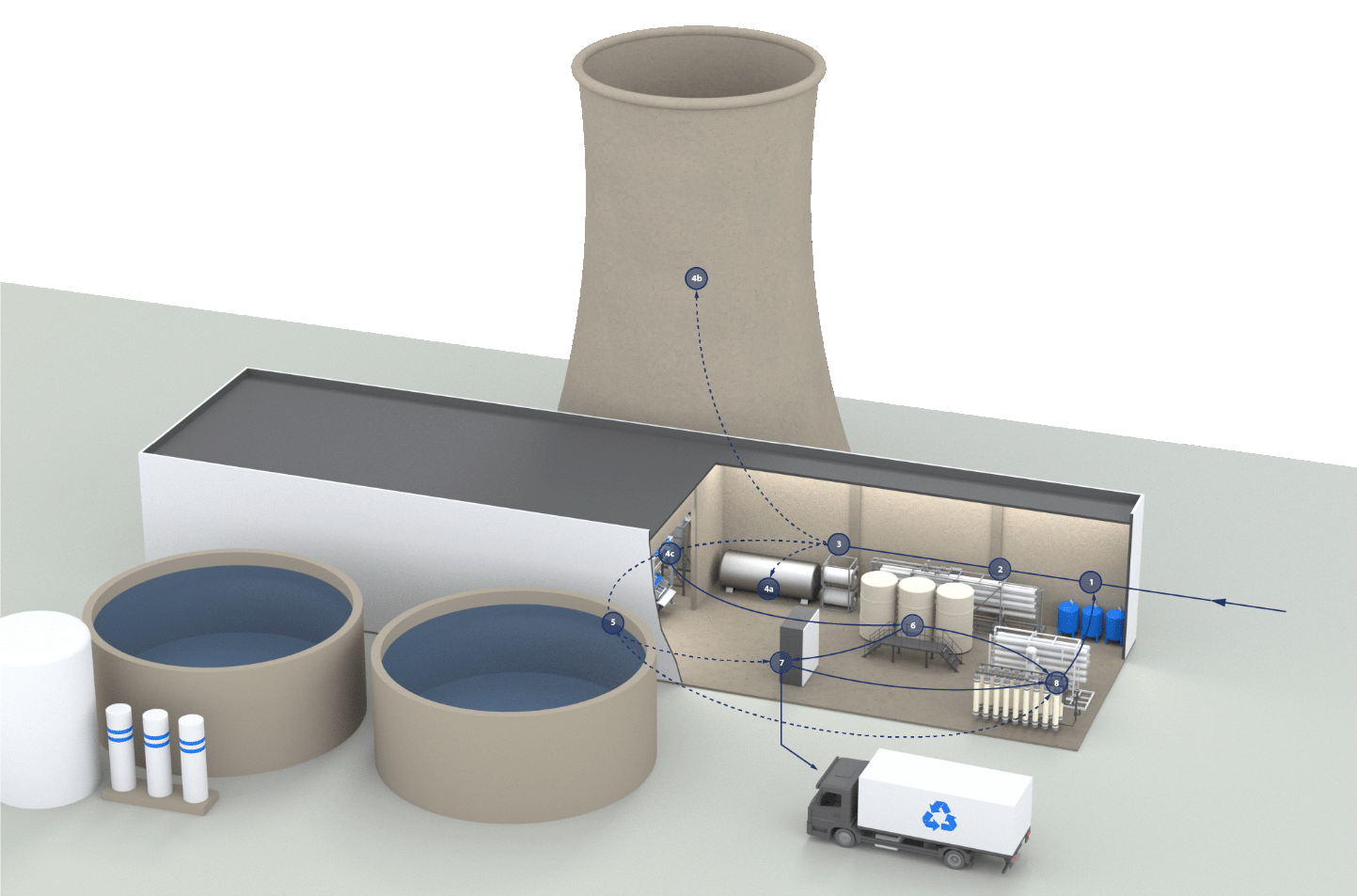

Industrial processes are very sensitive and need a water quality fit for purpose. Eco-Vision is an expert in designing the water treatment solution for your application. With this schematic drawing, we map out the options for industrial (waste) water treatment towards a closed loop. Eco-Vision? Change starts with a Vision

Pre-treatment (1) is needed for industrial process water whatever the water source you use: tap water, surface water, well water, reclaimed water. For many industrial processes, filtration (sediment and iron removal) and softening are required potentially followed by ultrafiltration. If chemical pre-treatment is preferred, than a perfectly designed dosing station must be added.

Reverse osmosis (2) removes the TDS load of the water and offers a pure permeate. Depending on the application (process water, ingredient water, water for steam,…), an EDI (3) or mixed bed polisher can be added if ultrapure water is needed. After the production line, the wastewater is treated either biologically (5) or physico-chemical (6) (IEX, RO, closed loop demineralisation) depending on the contaminants in the water. The remaining waste stream can be treated with evaporation (7) to reduce the volume of the waste maximally and to avoid or reduce transport cost to incineration. This is called minimum or zero liquid discharge. The permeate or condensate of the waste water treatment can be reused as process water (8).

Pre-treatment

RO

EDI

Boiler steam

Cooling tower

Production line

Biological wastewater treatment

Physico-chemical wastewater treatment

Zero liquid discharge – evaporation

Wastewater reuse (UF + RO)