100% SAFE

AND EMPTY IBC

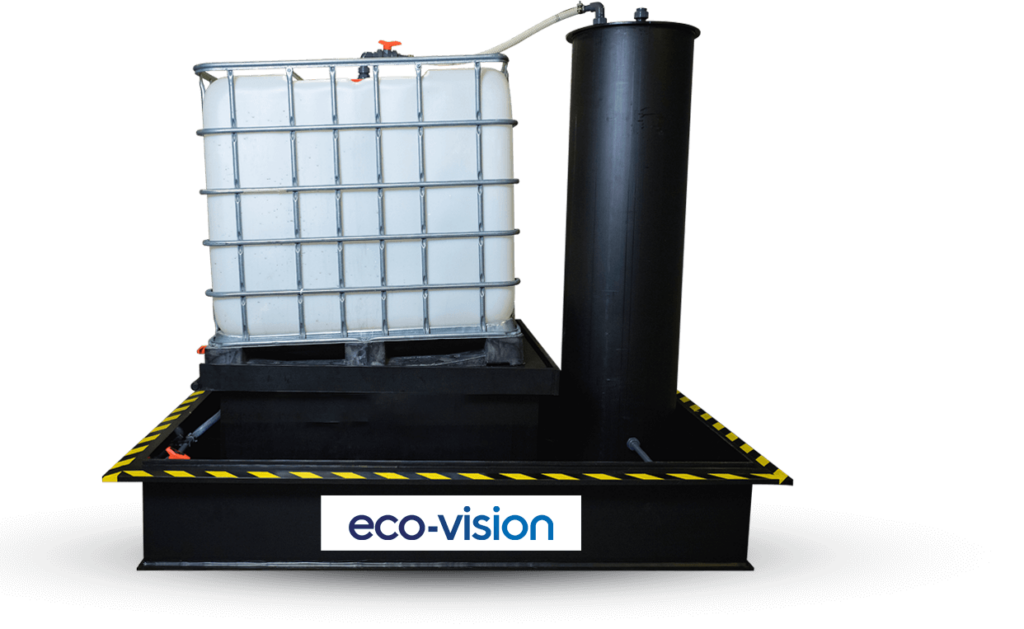

As standard, the dosing of chemistry is done by direct draining the IBC using a suction lance. This suction lance is loosely inserted into the opening on top of the IBC, making it difficult to empty the IBC completely. A Safe IBC system is provided to solve this problem. The Safe IBC system consists of a PE drip tray containing an automatically tilting IBC platform connected to an interim tank to ensure a interruption-free dosing system.

SAFE IBC DEVELOPED BY ECO-VISION

The IBC is located on the designated platform. A chemical- and aeration hose ensure a double coupling of the IBC to the small interim tank. Once the IBC drain valve is opened the content of the IBC automatically level with that of the small interim tank. The dosing pump (1 or more) is connected to the bottom of the interim tank. Due to its higher position, the IBC will empty faster than the buffer tank. The interim tank still contains a spare volume of chemistry (+/- 100 liters or more can be chosen), which gives the operator the opportunity to safely and easily replace the IBC without a production stop.

SAFE IBC SYSTEMS IN USE

Mieke – Hydro Building Systems Benelux

Hydro Building Systems Landen has also opted for Safe IBC. Safe handling of chemical products and no more waste.

Peter – Ebema

We have been using the Safe IBC system for more than a year. Clean and especially safe changing of barrels. We are very satisfied with it. Cost reduction of product because the barrel is completely empty. Top system.